|

Tri-Drive for

Pink Triangle

Turntables

There are few inherent problems with the esteemed Pink Triangle

turntable, but one of them is the axial play that can occur at the top

of the bearing housing.

Although the mass of the turntable tends to centre the pivot ball of the

bearing into the centre of the sapphire cup, there is a sideways pull

from the drive belt pulling the platter towards the motor. This effect

has a tendency to pull the pivot ball in the bearing to the edge of the

sapphire cup.

To help correct this,

we have re-positioned the motor onto the sub-chassis, inline between the

platter spindle and the tonearm board, similar to the PT

Anniversary thus producing a better balanced system. Also, If

the platter is driven from three equal points about its circumference,

then the balance of the platter is much improved. To achieve this, we have placed two pulleys and the motor pulley equally

spaced at 120° about the circumference of the belt recess in the

platter.

The result of all this, is an unbiased

rotation that is true to the centre of the platter bearing and produces

a much enhanced sound quality which is deemed by many as being the prime

enhancement that is overlooked by turntable manufacturers.

Also, due to the platter now having a balanced

drive, there is less 'judder' when the motor is switched on or when the

speed is changed, so there is less likelihood of the belt jumping off

the platter.

Fitting the drive belt is made much

easier by using a split platter as shown below.

The Tri-Drive conversion

can be used on the following Pink Triangle turntables: -

PT 1, PT Too, and PT

Export.

|

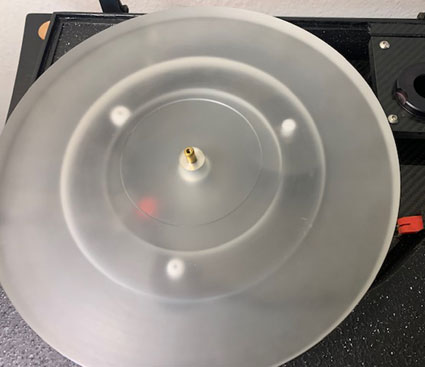

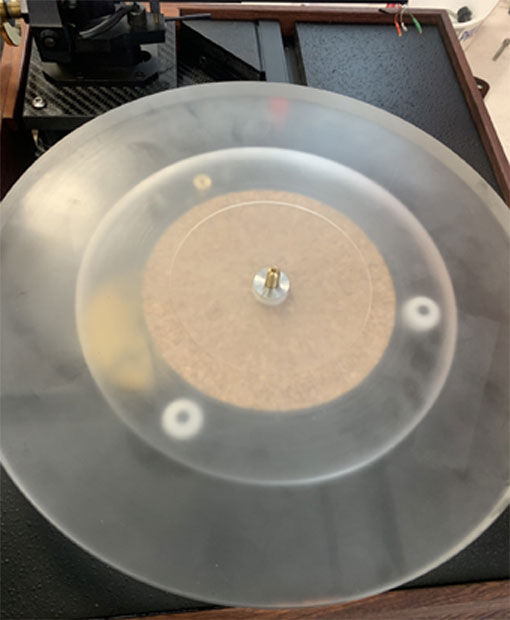

The Split

Platter

If you have a

PT turntable, you will probably agree that one of the problems

might well be 'fitting the drive belt'. This minor problem is

made no easier with the PT Anniversary where you have to fit the

belt around the additional pulleys. To make this problem

disappear we have modified the acrylic platter so that it is

constructed from two pieces as shown in the central photo below.

This type of system is used by other turntable makers such as

Funk, Linn and many others.

This

modification also greatly reduces the risk of the sapphire

bearing being damaged when changing the drive belt.

The smaller

platter is easily assembled onto the turntable main bearing, and

the drive belt fitted in place around it and the motor pulley.

The larger part of the platter can then be placed on top of the

smaller platter to finish the assembly. Please contact us

if you are interested in having your platter converted to a

split platter, with or without the optional cork lining on the

sub-platter. |

|

|

|

|

|

Above

are photos of the Split Platter which can be made by

modifying your platter. |

|

| |

Comments

from a PT enthusiast who bought the 'Option 3'

kit, photos

of his progress are shown after his comments.

Yes, I

do think it sounds a lot better. I’m not in a

position to do any measurements yet as my preamp

developed a fault just after lockdown so will

have to await its return....

I would

say that there is probably a lower level of

background noise, venue acoustics are clearer,

the infamous “tunes in bass” are clearer. I

think dynamics of music are probably handled

more cleanly with less congestion in louder

passages and layering of instruments- harmony

clearer as a result.

So far

listened a mixture of original and digitally

re-mastered recordings. Mixture of

classical/opera/ska/rock (well, Dire Straits),

Ska and George Melly.

I might say

the sound is perhaps more natural - dynamic.

My wife has

a cherished (mono) recording of Walton’s facade

which we are both enjoying (very important!).

Definitely

worthwhile doing - just got to decide on new

cartridge eventually! Mark W.

Bristol.

The Tri-Drive

Upgrade Conversion is available in 3 options

: - |

|

Option 1

This upgrade kit consists of : -

-

Tempate 1, this is to be used to mark

out the hole positions for drilling in the for

sub-chassis, so that it will accept the Tri-drive

pulleys and the motor mounting.

-

Template 2, to be used to mark out the

hole positions in the Top Plate.

-

Drive pulleys.

-

Tri-Drive pulley mounts, including

screws and nuts and washers.

-

Motor mounting, including isolation

spacers, screws, nuts, and washers.

-

Rear suspension mount assembly.

-

Larger Drive-belt.

|

|

|

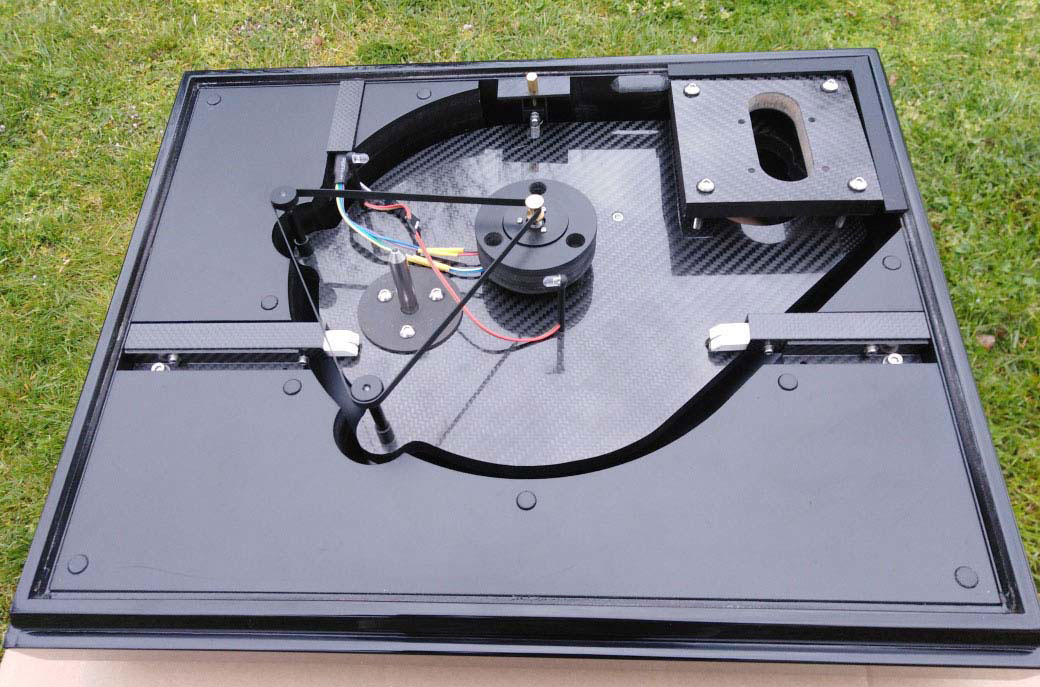

Option 2 :

This

upgrade kit consists of : -

-

Carbon fibre composite Sub-Chassis, pre-drilled to

accept the motor mounting, pulley mounting and

bearing assembly.

-

Tri-Drive pulleys.

-

Tri-Drive pulley mounts including screws and nuts

and washers.

-

Motor mounting, including isolation

spacers, screws, nuts, and washers.

-

Rear suspension mount assembly.

-

Larger Drive-belt.

|

|

|

Option 3 : -

This conversion upgrades your turntable to

Anniversary standard, it is not a DIY kit, it is

assembled and completed by True Point Audio from your

donor PT turntable. It is considered by many to be the

ultimate upgrade.

-

Your plinth

is stripped and HDF

segments are inserted, thereafter the interior is painted matt black.

-

New Carbon fibre composite Sub-Chassis, drilled to accept the

motor mounting and pulley mounting and bearing assembly.

-

New carbon fibre composite armboard.

-

Tri-Drive pulleys.

-

Tri-Drive pulley mountings.

-

Rear suspension mounting.

-

New larger drive belt.

-

New acrylic Top Plate.

Please contact us if you

require any further information on any of the above

options. |

|

|