|

Rigid, Lightweight

ARMBOARD for Rigid, Lightweight

ARMBOARD for

Pink Triangle

Turntables

The armboard shown above on the left is the old type made

from aluminium sheet, the one on the right is the new, much improved type prior

to drilling the hole for the tonearm.

These attractive, lightweight armboards are

a specially constructed sandwich of carbon fibre sheet, foam and carbon fibre

sheet . The carbon fibre sheet gives it its rigidity and modern looks, while the

resin impregnated foam helps abate transient resonance. The armboard is pre drilled to fit

straight onto your Pink Triangle turntable. All that is required is the hole/s for

the tonearm which we can put in for you.

Technical Details

Quasi-Isotropic Layup

To create a more uniform distribution of strength, all our sheets are

manufactured using both layers of 0°/90° and 45°/-45° oriented reinforcement in

what is known as quasi-isotropic fibre orientation. Carbon fibre sheets using

this layup technique offer improved stiffness across their diagonal axis and

significantly improved torsional stiffness.

Laminate Composition

The matrix used is a high performance epoxy resin which offers excellent

mechanicals, clarity and improved UV stability. The high temperature cure

maximises the mechanical strength properties and results in a Tg (glass

transition) of 80°C.

To achieve maximum stability and flatness in the sheets, we used 'balanced'

laminates for all sheet thicknesses. This means that the fibre type, weight and

weave is symmetrical from the front to the back ply..

|

Our Light weight Armboard kit consists

of: -

-

1

Carbon fibre composite armboard

-

1

Allen Key

-

4

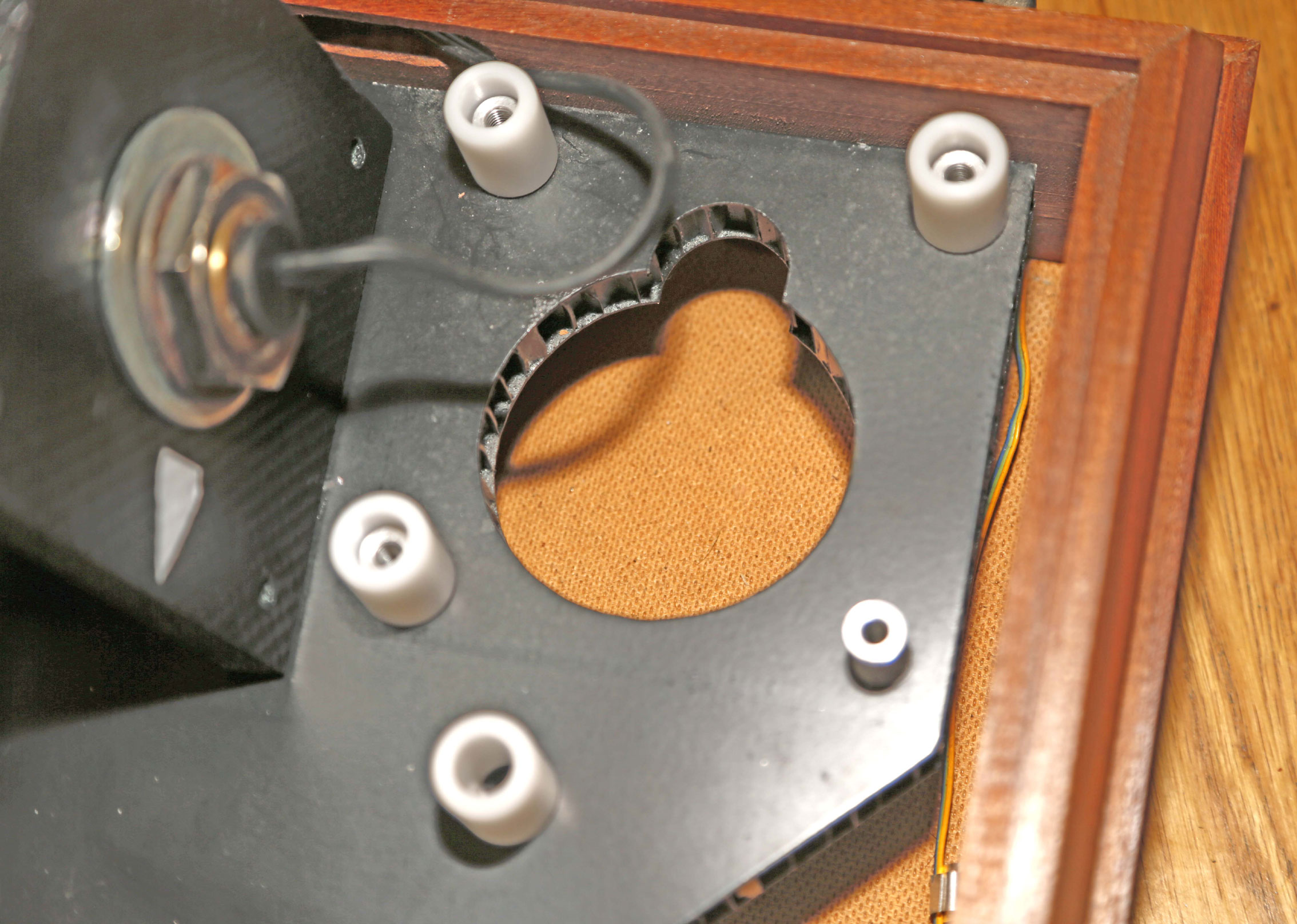

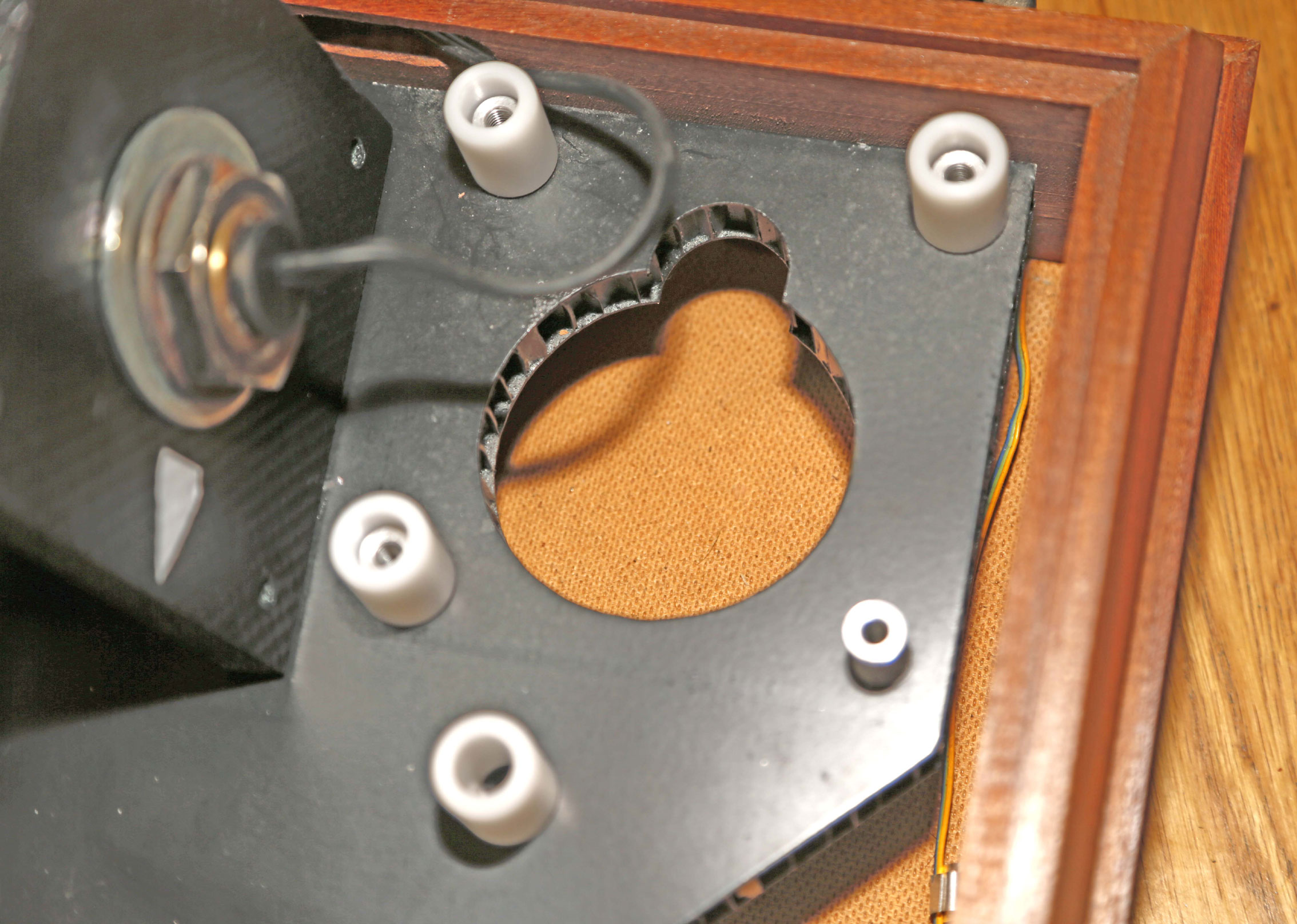

Black spacer Tubes (white shown in photos for clarity).

-

4

Stainless steel M5 Button Head socket screws.

|

|

Fitting Instructions:-

Ensure the

electrical supply to the turntable is switched off and the mains plug

plug removed from the electrical socket.

Carefully remove the tonearm and

original armboard.

Place the plastic spacers over

the aluminium stand-off posts fitted on the sub-chassis as shown in the

photos.

The spacers

supplied have been made to set the top surface of the armboard to the

same height as the original armboard.

When fitting it, to make sure

the orientation is correct, there is a notch filed on the underside edge of

the armboard, this must face forward.

If you weigh your

existing armboard and compare its mass against the carbon fibre one,

then the difference in mass can be added to the carbon fibre

armboard using the stick on weights provided.

Finally,

when tightening the screws to secure the armboard to the

sub-chassis, do not over-tighten them otherwise you will dent the

armboard, they only need nipping up.

If you have any special

modifications needed concerning the base height of your tonearm, please

discuss this with us when enquiring.

|

|

|

We have marked the underside

of the armboard with sticky tape to show which side faces to the front

of the turntable.

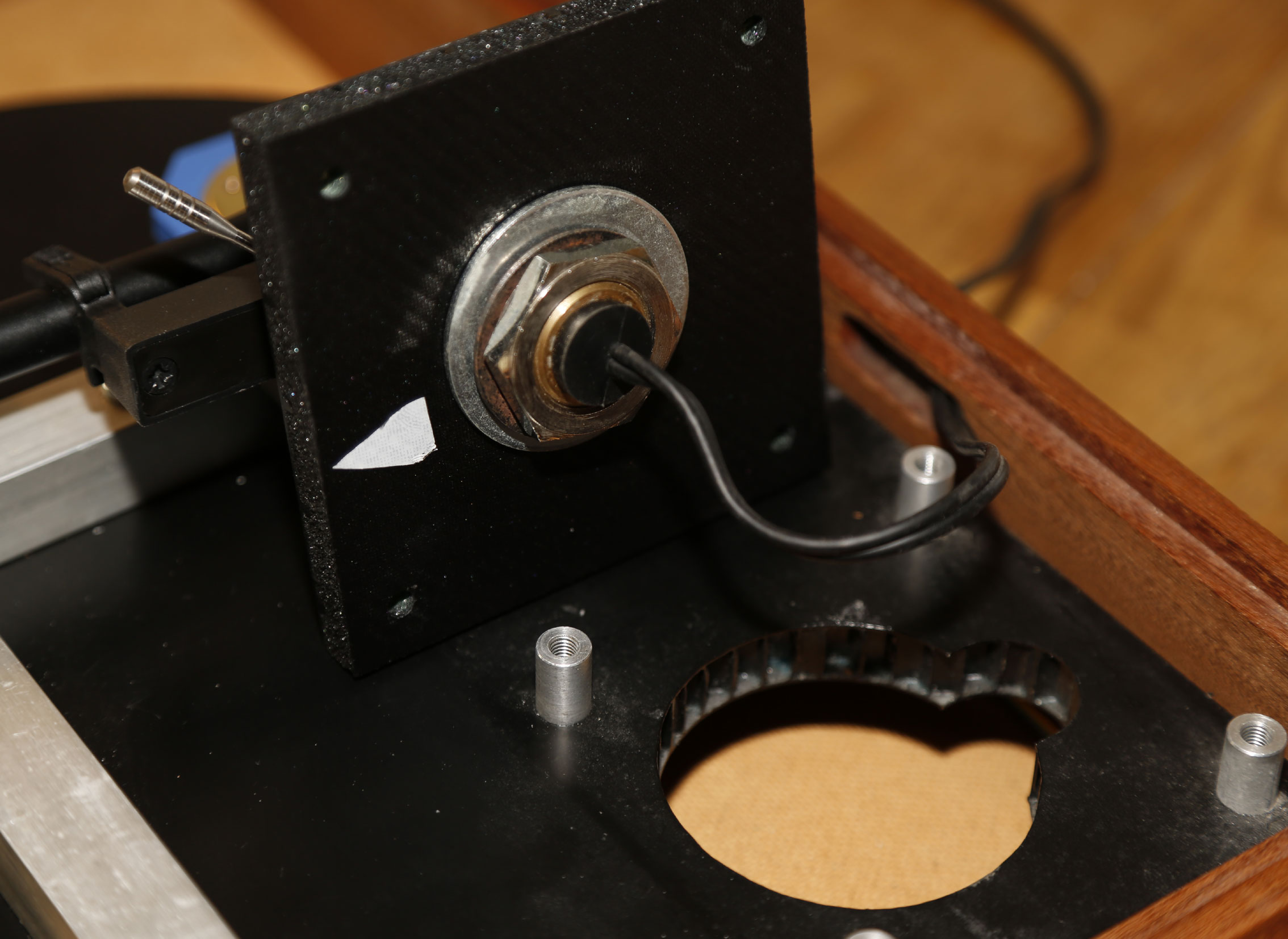

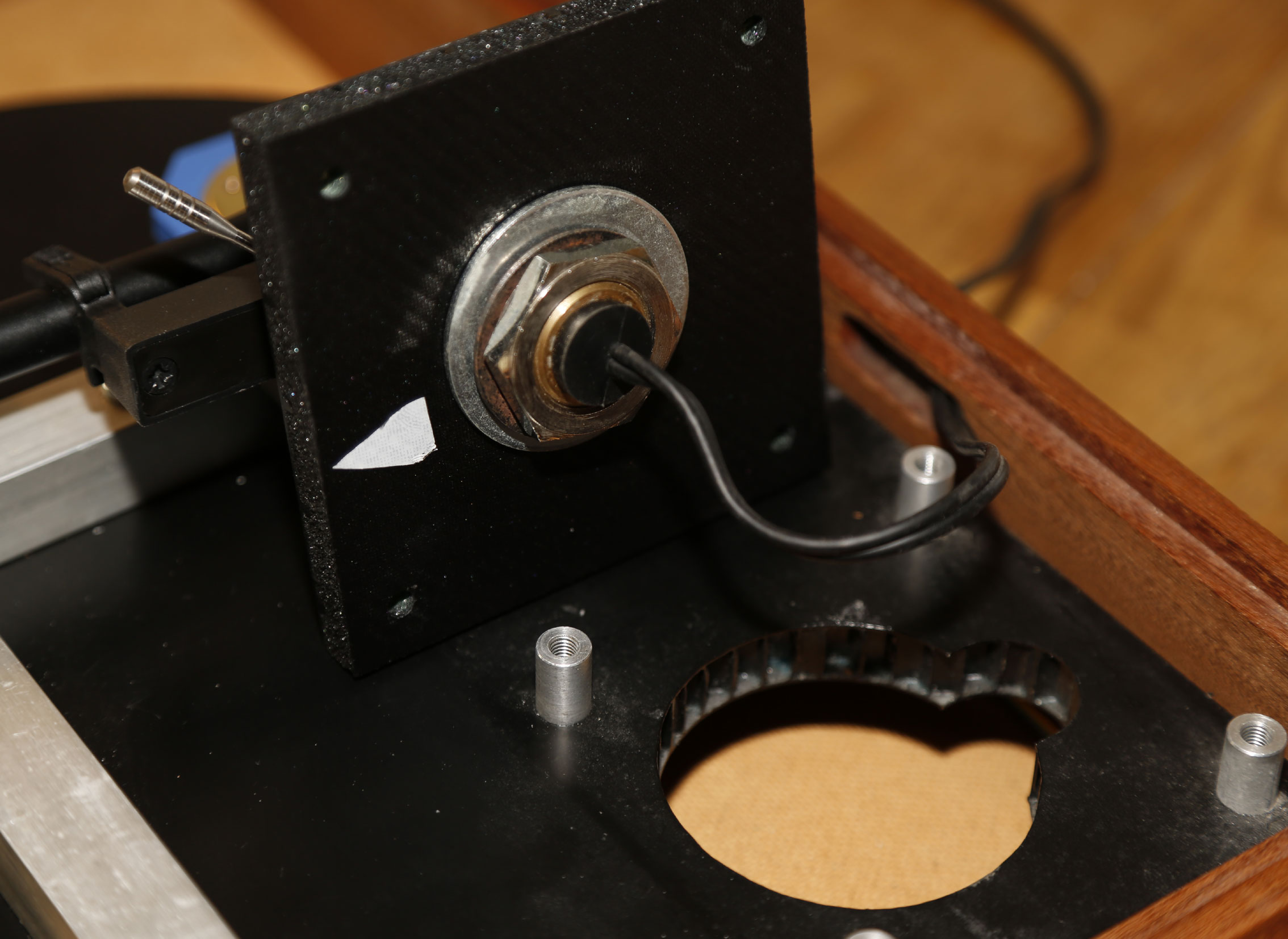

Assuming the armboard is drilled to take your type of tonearm and the

plastic spacers are in place, carefully

fit the tonearm to armboard.

If the armboard is not drilled,

care must be taken when drilling the hole\s to ensure the correct

spindle distance to the centre of the tonearm, and the hole\s size are

as per tonearm manufacturers recommendations. |

|

|

Using the black anodised

aluminium screws, fix the armboard onto the spacers as shown in the

photo.

It is only necessary to 'nip'

the screws up, do not over tighten them. An Allen key is supplied for

your convenience. |

|

|

All done, now connect your

tonearm cable and check the VTA and cartridge alignment is correct. If

it is not, then adjust them as per the tonearm manufacturers

instructions.

Photo's courtesy of Darren Ladd |

|

|

All done, now sit back and

enjoy your music |

Please contact us for price and delivery.

Copyright © True

Point Audio Ltd

|

Rigid, Lightweight

ARMBOARD for

Rigid, Lightweight

ARMBOARD for